Izjava o privatnosti: Vaša nam je privatnost vrlo važna. Naša tvrtka obećava da neće otkriti vaše osobne podatke bilo kakvom prozonskom izričitoj dozvoli.

Ambalaža: Kartonska kutija

Produktivnost: 1000000000 pcs/week

transport: Ocean,Land,Air

Mjesto podrijetla: Kina

Sposobnost isporuke: 7000000000 pcs/week

Potvrda: GB/T19001-2008/ISO9001:2008

HS kod: 8541401000

Luka: SHENZHEN

Način plaćanja: T/T,Paypal

Inkoterm: FOB,EXW,FCA

Model br.: 509FIRYGC

marka: Najbolje LED

Vrsta Opskrbe: Izvorni proizvođač

Referentni Materijali: tablica podataka

Mjesto Podrijetla: Kina

Vrsta: LED

Vrsta Paketa: Kroz Rupu

primjena: Electronic Products

Luminous Intensity: High Directivity

Color: IR And Yellow Green

Formation: Gold Thread

Inner Packing: Anti-static Bag

Current: 20mA

Beam Width: 20 Degree

Polarity: Cathode on short pin

Wavelength: 880nm + 570nm (±10nm)

Lens Type: Clear lens

The file is encrypted. Please fill in the following information to continue accessing it

How does a 2 color LED work?

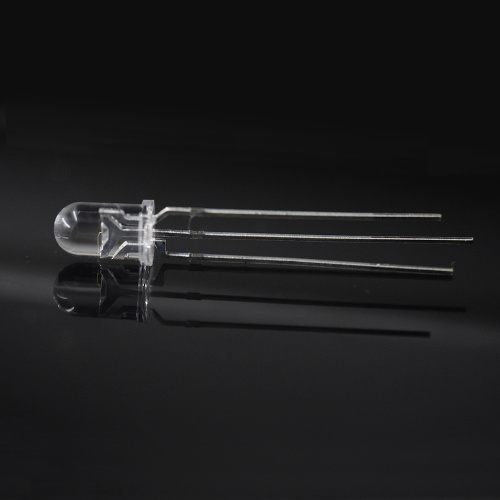

Bi-color LED can be package with SMD LED or through-hole LED Lamp type. In this 509FIRYGC, it's 5mm through-hole LED type with clear lens. Which can emits the full brightness from the LED chips. Then how does it work? Just following the datasheet and connect the correct polarity electric current, this LED will light up the color as you need. As the name, Bi-color LED lamps means that have two color inside one single LED package. We package yellow green color and IR LED (880nm LED) inside this LED Lamps case, which can make sure this 5mm bi-color LED can work good for status indicator and signage applications.

Size of 5mm bi-color LED:

*This size are also available in IR LED, UV LED, Red LED, Yellow LED, Green LED, Amber LED and Blue LED;*

Electrical Optical Characteristics(Tc=25 ℃ )

| Parameter | Symbol | Min | Type | Max | Unit | Test condition | |

|

Forward Volatge |

IR | VF | 1.3 | 1.4 | 1.6 | V | IF=20mA |

| Green |

|

2.2 | 2.5 | IF=20mA | |||

| Luminous Intensity | IR |

IV |

150 |

|

250 | mcd |

IF=20mA |

| Green |

|

|

10 | mw/sr |

IF=20mA |

||

| Peak wavelength | IR |

λP |

875 | 880 | 890 | nm |

IF=20mA |

| Green |

|

570 | 575 |

|

|||

| Half width |

λ△ |

|

15 |

|

nm |

IF=20mA |

|

| Viewing half angle | 2θ1/2 |

|

20 |

|

deg |

IF=20mA |

|

| Reverse current | IR |

|

|

5 | uA | VR=5V | |

Production progress for through-hole LED:

Storage conditions

1. avoid continued exposure to the condensing moisture environment and keep the product away from rapid transitions in ambient temperature;

2. LEDs should be stored with temperature ≤30℃ and relative humidity<60%℃;

3. Product in the original sealed package is recommended to be assembled within 72 hours of opening;

4. Product in opened package for more than a week should be baked for 6-8 hours at 85-10℃;

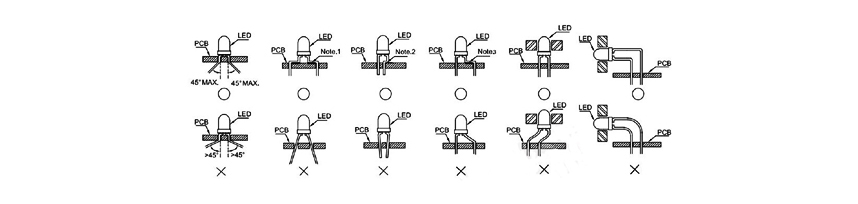

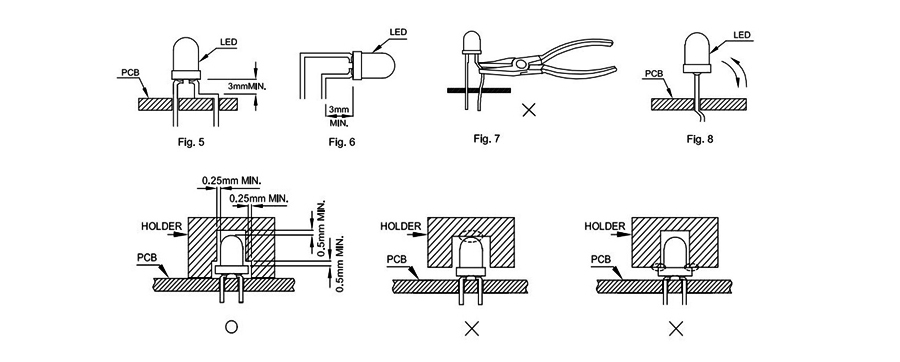

LED MOUNTING METHOD

1, The lea d pitch of the LED must match the pitch of the mounting holes on the PCB during component placement ;

Lead-forming may be required to insure the lead pitch matches the hole pitch ;

Refer to the figure below for proper lead forming procedures ;

Do not route PCB trace in the contact area between the leadframe and the PCB to prevent short-circuits ;

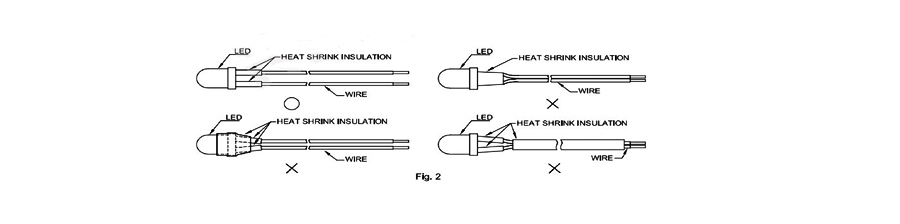

2. When soldering wires to the LED, each wire joint should be separately insulated with heat-shrink tube to prevent short-circuit contact.

Do not bundle both wires in one heat shrink tube to avoid pinching the LED leads ;

Pinching stress on the led leads may damage the internal structures and cause failure ;

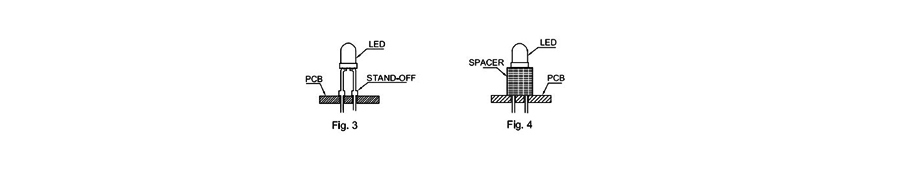

3. Use stand-offs(Fig 3)or spacers(Fig 4)to securely position the LED above the PCB ;

4. Maintain a minimum of 3mm cl earance between the base of the LED lens and the first lead bend (Fig. 5. Fig. 6)

5.During lead forming, use tools or jigs to hold the leads securely so that the bending force will not be transmitted to the LED lens and its internal structures ;

Do not perform lead forming once the component has been mounted onto the PCB ;

L ead Forming Procedures

1. Lead Forming Procedures ;

2 . Do not bend the leads more than twice (Fig. 7 );

3. During soldering, component covers and holders should leave clearance to avoid placing damaging stress on the LED during soldering(Fig 8) ;

4. The tip of the soldering iron should never touch the lens epoxy ;

5. Through-hole LED s are incompatible with reflow soldering ;

6. If the LED will undergo multiple soldering passes or face other processes where the part may be subjected to intense heat please check with Best LED for compatibility ;

tel: 86-0755-89752405

Mobitel: +8615815584344

E-mail: amywu@byt-light.comAdresa: Building No. 1 Lane 1 Liuwu Nanlian The Fifth Industry Area , Longgang, Shenzhen, Guangdong China

Izjava o privatnosti: Vaša nam je privatnost vrlo važna. Naša tvrtka obećava da neće otkriti vaše osobne podatke bilo kakvom prozonskom izričitoj dozvoli.

Ispunite više informacija kako biste brže kontaktirali s vama

Izjava o privatnosti: Vaša nam je privatnost vrlo važna. Naša tvrtka obećava da neće otkriti vaše osobne podatke bilo kakvom prozonskom izričitoj dozvoli.